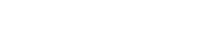

88x48.1 mm Stator Rotor Lamination for Series Motor

CD88481

motor core, motor rotor

CD88481 is mostly applied for regular series motors, such as milling machines, cutting machines, juice blender, spinners and etc. If the RPM is below 6000, it will be DC type. When RPM is higher than 6000rpm, it will be AC type. The outer diameter of stator is 88mm and the outer diameter of rotor is 48.1mm. The slots of rotor are 12 slots. Approved by IE2, IE3, and IE4 authentication.

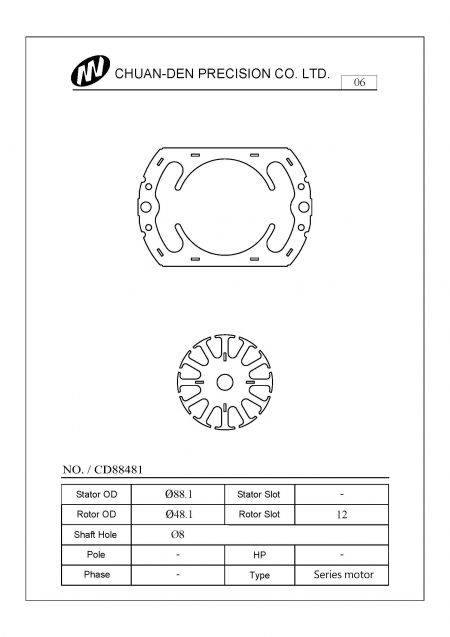

Excellent Material

Our silicon steel lamination coils, non-oriental type, are all directly from China Steel Corporation (CSC), China Steel is also the supplier for Telsa Automotive in Taiwan. There are several grades for choices, such as 50CS1300, 50CS800, 50CS600, 35CS470, and 35CS550...etc. 50CS1300 is widely used for making industrial motors. The iron loss is so low only 5.88 W15/50. Industrial motors applied with 50CS1300 is able to pass IE3 high efficiency testing. 50CS1300 is good enough for model TG10870, furthermore, customers can cost down by using 50CS1300.

By the way, if you want to know more about the iorn loss level, please kindly check Table 7: Typical electrical and magnetic properties of General and High Frequency Products. This table is quoted from China Steel Cooperation.

By the way, if you want to know much more of steel lamination, you can find the relative material grade table in our website.

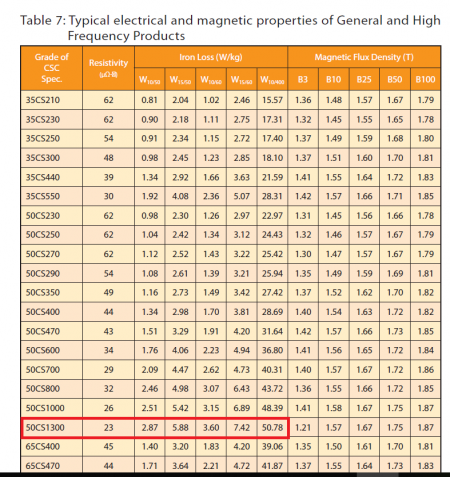

Pressing Mould

TayGuei use the Progressive Mold / Die to punch / Stamp all the stators & rotors. The mold is is made of Tungsten steel. The tolerance is 0.03 mm, and it can stamp 100 million times with lifetime warranty.

We have a professional team to design, make and do the maintenance of molds. If your mold/die is customized by us. We provide life time service for free. The lead time of customized mold is about 3 months with final approval sample included (FA sample).

Furthermore, we provide "Stepping Mold" for customer to do samll quantity production. We also provide " Laser cutting samples" for customers to check the design first before developing the mold. By doing so, they can figure out the problems (if any) in advance. Once they confirm the design by laser-cutting samples, they can proceed the mold developing.

Business Type

OEM/ODM:

With our rich experience on stators and rotors, we are able to provide you customization service if you need any change. Certainly, we can also support you to develop new prototype motor. For existing products, our team can do the trouble shooting and provide you best solution based on our 40-year experience. We even help our customers outsource the related components. You can do one-stop shop with us.

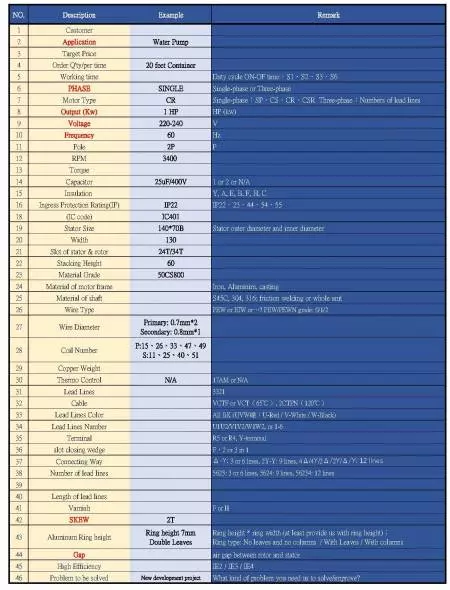

Below is the developing table of new motor. Please fill in it then reply to us when you have any demands about new motor project. This can save both of us time to communicate. If available, please provide us with the picture of the motor plate.

Some of our customers are looking for the service of"Winding". We have such service for sure but under a certain quantity. Please provide us with the winding data, such as wire type, wire diameter, coil numbers, coil weight…and so on. The fastest way is sending us one motor to evaluate then quote.

If you are planning to develop new fan motors,don't forget to send blades to us, too.

Interlock / Riveting

Finally, please be advised that those stators and rotors are with interlock technology. With interlock, the production is much faster and precisely. We can set the desire SKEW (for rotor) first. Then stators and rotors are stacked up automatically while stamping / punching progress. Therefore, we can speed up the production speed and reach massive production quantity.

We can provide several ways of stacking – sheet, interlock & welding. Especially when the stacking height is over 80mm, we suggest customers to do welding to make the stator conject firmly.

Finally, we would like to talk about the screw holes on stators. Depending on the design of motor frame, we can fasten the stator via the screw holes or via ditches. Please mark if you need screw holes on your inquiry.

Aluminum Die Casting

If you are looking for good quality aluminum die-casting, we are your top choice! Due to there are various kinds of shapes of aluminum die casting, please provide us the drawing or at least tell us the ring height. So that we are able to find the match one. Normally single phase motor is with 3mm~7mm aluminum ring, and three phase motor is with 7~15mm aluminum ring.

Pure aluminum die-casting and aluminum alloy die-casting are available. The material of our aluminum is 99.8%. If your industrial motors need better torque, you can take in consider aluminum alloy die-casting.

Customized aluminum casting mold is provided. Please provide us with your drawing to evaluate the cost. As to the lead time, it will be around 21 working days.

Order Quantity

Generally speaking, our orders are mostly CY / FCL shipment. Standard packing is cardboard boxes with wooden pallets. Our trade term is FOB Taichung Port. Certainly, we provide different trade term depending on our customer's request, such as CIF, CAS, DDP and so on.

Regarding to the standard models, we accept small order quantity for stators and rotors – 500 sets or even less. Although we have safety stock for standard models, the stacking height and the SKEW differs from applications. Sometimes, customers may have to wait for production arrangement and the lead time will be around 21 days.

As to the package of CFS goods, it will be in wooden case to provide better protection during the transportation. All stators and rotors will be sprayed with anti-rusting oil before shipment, and sealed in boxes. VCI paper is optional for long time shipment, such as to South American and Europe.

Free Sample

Understanding it’s a long term to do a new motor development project, we provide free samples of stators and rotors for customer to test. Based on our 40-year experience, we could suggest customers the suitable stacking height, SKEW, even the winding data (project case only). As to the express freight, it will be covered by customer's account number. You can choose Express – TNT, DHL, FedEx / Air parcel depending on your needs.

If you find the suitable stator and rotor from our website, please feel free to contact us for free samples. The lead time of samples is 21 days after confirming the specification, such as SKEW, material grade, die-casting type, shaft hole and so on. Please notice our standard lamination material grade is 50CS1300.

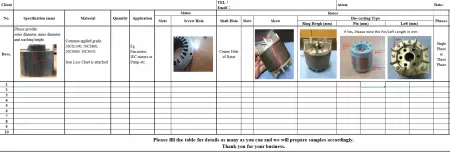

What if there is no corresponding stator and rotor for you, we also provide laser-cutting or stepping mold samples. The molds and samples are charged and will return the fee from the first trial order. Please contact us to get the table of sampe demand, we need to clarify your needs first then prepare your samples accordingly.

Specification

- ID #: CD88481

- Dimension: 88 x 48.1

- Stator: 88

- Rotor: 48.1

- Rotor Slots: 12T

- Shaft Hole: 8

- Application: Series Motor

- Files Download

Product List Download

We list the most common dimensions in a table. Those stators rotors are public mold and applied widely. Please notice that the first two numbers stand...

DownloadStator Rotor Lamination for Series Motor

This motor core is mostly applied for regular series motors, such as milling machines, cutting machines, juice blender, spinners and etc. If the RPM is below...

Download

88x48.1 mm Stator Rotor Lamination for Series Motor | Stator Rotors - All Industries Manufacturer | TayGuei

Located in Taiwan since 1984, TAYGUEI INDUSTRY CO., LTD. has been a stator and rotor manufacturer in the stamped parts industry. Their main stator rotor products include, 88x48.1 mm Stator Rotor Lamination for Series Motor, rotors, stators, motor cores, motor parts, fan motors, silicon steel lamination, rotor lamination, laminated stators, intelligent motors and servo motors, which are sold to over 15 countries.

With almost 40 years experience in standard dimension and customization service. We are expertise in mould development and maintenance that guarantees our high quality products. The main service philosophy is COMPLETE YOUR MOTOR. TayGuei believes helping our client to produce a better motor is priority than any other else. Stator and rotor stamped from high grade steel, 3µm precision, long service life, low power consumption, excellent efficiency and 3 week lead time.

TayGuei has been offering customers motor stators and rotors, both with advanced technology and 39 years of experience, TayGuei ensures each customer's demands are met.